Reducing yeast and mold contamination

By: Bill Rufenacht | Technical Specialist, Dairy Connection Inc.

One of the more prevalent problems we see in dairy products is the appearance of unwanted yeasts and molds. Spoiled products account for as much as 30% of the food waste in the US according to the FDA. Yeast and mold contamination is responsible for a major portion of that waste. Consumers tend to shop with their eyes first, making it unlikely that a package with visible mold will ever be purchased.

About Yeast and Mold

Although yeasts and molds are both types of fungi, they differ in several aspects:

Molds

Molds are multi-cellular organisms that grow by producing filamentous structures called hyphae. Hyphae form networks that are referred to as mycelia. Mold colonies normally appear as hairy or fuzzy, growing best in damp environments. They can survive on many different substrates like food, soil, or materials that are decaying. Molds are decomposers breaking down complex organic materials into simpler compounds. Molds reproduce by means of spores which are easily distributed via air currents, in water, on shoes, clothing, cardboard, or pallets. Anything coming into your facility can bring mold spores with them. Some molds produce toxins (mycotoxins), which can cause health issues in humans and other animals. Exposure to molds may also lead to respiratory issues or allergic reactions in sensitive individuals. Molds are important to the cheese industry in the production of blue and white mold cheeses. Though many molds are not harmful, it is likely that consumers will avoid purchasing any product with unexpected visible mold growth.

Yeasts

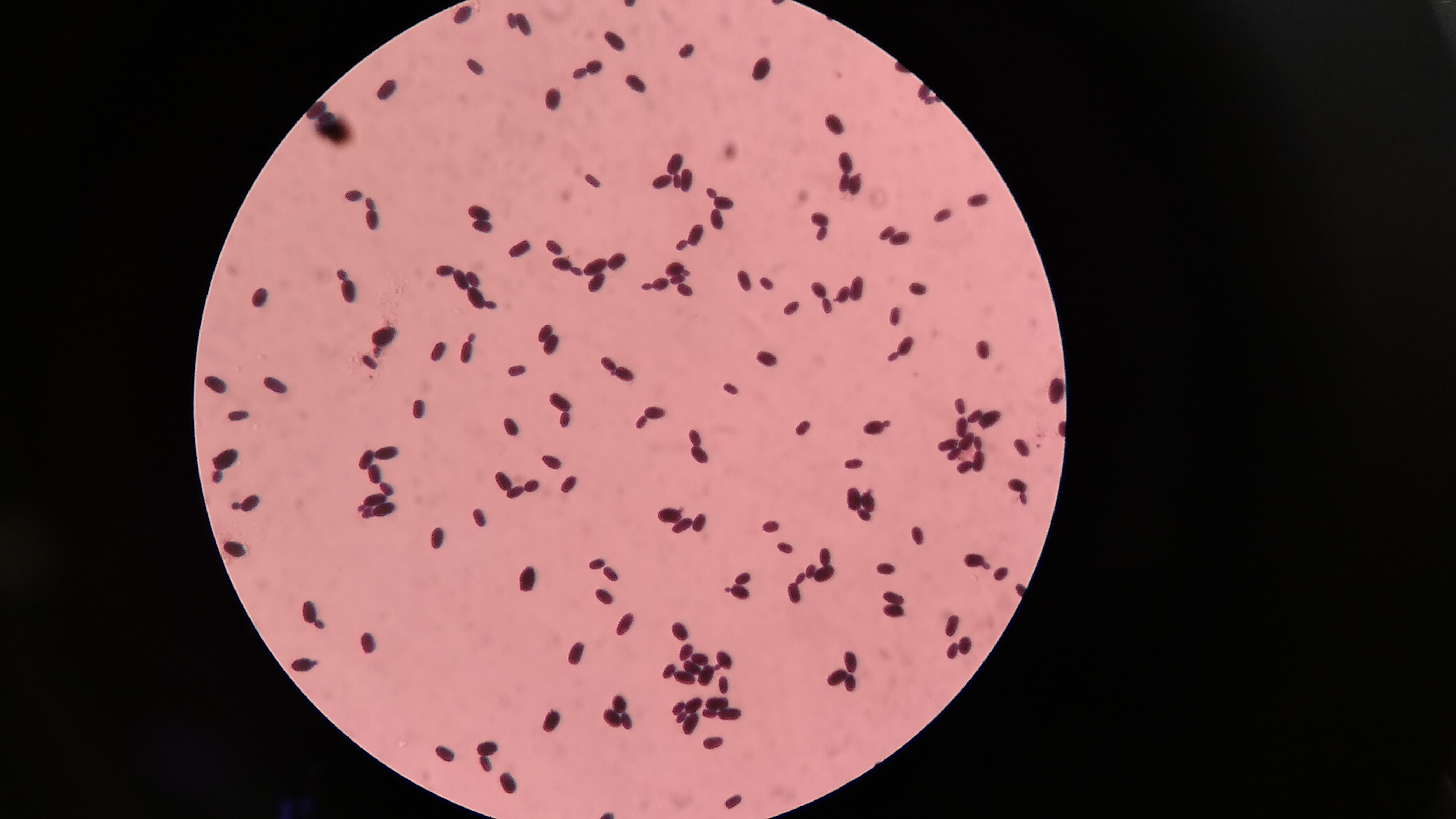

Yeasts are single cell (unicellular) fungi which typically have round or oval shapes. They do not form hyphae and most reproduce by budding. Yeasts are found in sugary environments or in fermentation environments. They are important in the baking and brewing industries where their ability to ferment sugars to produce carbon dioxide and alcohol is desirable and utilized. While yeasts do not typically cause health effects, some can cause allergic reactions or infection. In dairy they can cause undesirable flavors, aromas, and unwanted gas (see photo at the top of this blog post). Yeasts are brought into a facility easily, gaining entry through many of the same paths as molds.

Both types of organisms are ubiquitous and keeping them out of our facilities and products requires a multi-pronged approach.

How do we keep them out of our facilities?

Inspecting Incoming Materials

Keeping these organisms from entering our facilities can be challenging. We can begin by making certain that incoming trucks and the materials delivered on them are clean, and free of obvious contamination. This includes cartons, pallets, and drivers. Limiting drivers’ access to your facility can be helpful. Maintaining a log which verifies the inspection and satisfactory condition of incoming trucks and materials is good practice. After your initial inspection, Certificates of Analysis are also valuable to ensure that incoming ingredients are within specifications and free of yeast and mold.

Air Handling

Keeping production and packaging rooms under positive filtered air pressure is important. This means that the direction of conditioned air flow should be out of the areas where product is exposed to the plant environment. Rooms in which finished products or ingredients are exposed, such as the make room, packaging room, or affinage areas pose the greatest risk. These rooms require filtering the air from your heating or cooling source with HEPA (High Efficiency Particulate Air) filters that are fine enough to eliminate mold spores. This requires a HEPA filter with a MERV (Minimum Efficiency Reporting Value) rating of 8 or above. The MERV rating of a filter describes the efficiency of reducing the level of 0.3-to-10-micron sized particles in the air passing through. A MERV rating of 11 – 13 will filter even the smallest mold spores, but you should verify that your system can handle the increased air flow resistance these higher ratings require. A higher MERV rating means higher filter efficiency. The goal is to keep outside unfiltered air from entering areas where products are exposed. Grade A products like buttermilk, kefir and yogurt are normally exposed for only short periods of time due to being fermented in enclosed tanks and moved via pipeline. This decreases the chance of Grade A products being contaminated by air-borne yeast or mold.

Employee Traffic, Shoes, and Clothing

We would like to keep all clothing and shoes that have been outside of the production, packaging, and affinage areas from entering those rooms. This requires footwear and clothing that is only worn in those areas. Many production facilities will have smocks or lab coats that are laundered on site or by a commercial laundry for their employees. This reduces the chance of employees bringing in mold spores on their clothes from outside the plant. Training employees to have a solid understanding of how easily spoilage and pathogens organisms can travel into and through your plant is critical. Foot foamers are also key in decreasing the chance of traffic from other areas of the facility bringing contaminants to production and packaging areas. Visitors should be issued disposable lab coats and shoe covers from your facility – or kept out of production and packaging areas.

Other Considerations

If you must bring carts or pallet jacks into production or packaging areas it is good practice to clean and sanitize them regularly. Moving this equipment through foot foamers can be effective at sanitizing wheels. Try to minimize or eliminate the need to bring wood pallets or cardboard into these areas as those materials can allow the growth of mold colonies or bring in spores.

Additional Strategies

Bioprotective Cultures

There are cultures available to add to your dairy products that inhibit yeast and mold growth. These are categorized as protective or bioprotective cultures. Check out our earlier blog post about bioprotective cultures to learn more about them. International Flavors & Frangrances (IFF) has added some new Holdbac® protective cultures since that information was originally included in our blog. Protective cultures such as IFF's Holdbac® series or Novonesis' FreshQ® series are added at the same time as your starter cultures. The strains have been selected not to contribute to acidification or sensory characteristics of your finished product. They do not need to be declared separately on your ingredient label as they would be included as part of the “culture” statement. As they grow in your products, they produce organic acids, which are the agents that inhibit the targeted undesired organisms.

Natamycin

Natamax® is the IFF brand name for their preparation of natamycin. Natamycin is extremely effective at eliminating mold growth from your products. Natamycin is fungicidal, meaning it kills molds. Bioprotective cultures are fungistatic, meaning they will inhibit growth, but can be overwhelmed by high counts of yeast or molds. Natamycin is extremely effective at reducing or eliminating yeast and mold growth on your finished product. Although it sounds artificial, it is a natural fermentate of Streptomyces natalensis. A team from Gist-Brocades (later DSM) originally isolated the organism in soil from Africa. DSM brought natamycin to the food industries under the brand name Delvo Cid in 1967 for selected applications. Although it is a natural product, the name has the appearance of being an artificial chemical. Some retailers have dictated that it is not used on products they distribute because they (and their customers) do not want it on the label.

The MicroGard® product line

IFF offers the MicroGard® product line, another potential resource in the campaign to control mold and yeast. These products consist of natural anti-microbials resulting from culturing various ingredients then drying the resulting product. They are offered as powders which are targeted to control yeasts, molds, and some pathogens in various applications. They are produced by fermentation of dextrose, milk, or wheat for incorporation into food products. They were developed originally for dairy applications to reduce yeast, mold, and potential human pathogens. In addition, MicroGard® can extend shelf life and contribute to improved sensory characteristics. Typical dairy applications include yogurt, dairy beverages, sour cream, dips, and cottage cheese. MicroGard® usage rates range from 0.5 to 1.5% for most dairy applications. These products are packaged in 50-pound bags, which means they are not a practical solution for all producers.

Finally

Eliminating yeast and mold from your dairy products is best accomplished by keeping those organisms out of your facility. Because we do not have perfectly designed facilities and we deal with employee foot traffic and behaviors, some level of contamination is probably inevitable. A combination of the above strategies can be helpful in keeping your finished products free from yeasts and molds.

Recent Blog Posts

-

Overview of Coagulant Types

By: Bill Rufenacht | Technical Specialist, Dairy Connection Inc. Below is a broad overview of the v …11th Feb 2026 -

2026: Looking ahead together at Dairy Connection

By: Katie Phillips | President & CEO, Dairy Connection Inc. As we step into January, I’m feeling exc …16th Jan 2026 -

Celebrating National Cheese Curd Day, October 15th

By: Valerie Tobias | Marketing Coordinator, Dairy Connection Inc. I'm a Generation X-er who's lived …14th Oct 2025