Choosing a yogurt culture

By: Emily Harbison | Technical Specialist, Dairy Connection Inc.

We stock roughly twenty different yogurt cultures and have access to at least 100 more. If you’re in the market for a starter, how do you choose between all of them? Below are some of the major factors to consider as you research and develop your product.

KNOW YOUR PRIORITIES

Target flavor profile

Generally, the U.S. yogurt market is looking for a flavor profile that is more mild, like pudding, and less like historically tart yogurt, but we have a variety of culture options to reach any flavor target.

Aside from finished pH, TA, and acid taste, the bacteria in your starter culture contribute flavors including, but not limited to, acetaldehyde (which tastes fruity, similar to green apple), and both acetoin and diacetyl, which have buttery character.

Target body and texture

Unless specific texture analysis or viscosity instrumentation is used to measure your yogurt, comparing your yogurt to a nationally-distributed brand’s texture may be useful as you describe your desired body and texture.

Species present

By definition (the standard of identity), yogurt contains Streptococcus thermophilus and Lactobacillus bulgaricus, but many yogurts contain additional cultures. Your market demand may call for cultures like Lactobacillus acidophilus, Lactobacillus casei, or Bifidobacterium. Some yogurt starters come with these other organisms included, but they may be added separately as well.

Processing technique

Method of manufacture is usually dictated by current infrastructure and equipment. Being familiar with cup-set vs. vat-set make procedure is important, as it is almost impossible for one to mimic the other.

Stabilizers

Yogurt culture body strains can help avoid the use of stabilizer, but they are not a replacement. Certain body and texture profiles are only attainable with stabilizers. For example, the use of gelatin in yogurt gives an inimitable shininess. From a labeling standpoint, some markets are looking for stabilizer-free yogurt or the absence of gums and modified food starches.

Sugar

Time of addition – if all the added sugar is in the fruit-on-the-bottom, your cultures won’t notice

Content – Sugar will generally decrease the rate of acid production from your culture, but some cultures are more sugar-tolerant than others. (granulated cane sugar, syrups, fruit purees, and protein powders are all potential sugar sources)

Protein

Processing technique – if you are fortifying protein in (e.g. adding NFDM prior to pasteurization) or concentrating (e.g. bag draining after fermentation)

Content – Protein can act as a buffer, requiring that your starter culture produce more acid in order to reach the same pH level

Allergen

Is your product intended to be vegan or dairy-free? From chemical hazard analysis, milk allergens should be at the top of your priority list when shopping for any ingredient.

Are you producing a goat, sheep, or other non-bovine yogurt? Are your customers buying your product to avoid bovine dairy? Please consider this when choosing your culture. From an allergen declaration and labeling standpoint, all milk is treated the same, bovine or otherwise, but your customers may have concerns that you can accommodate.

ECONOMIC

Fermentation time

See above, but it also can affect your bottom line if your starter is the difference between making multiple batches of yogurt per day.

Cost-in-use

Looking at yogurt prices alone, you can expect your culture to contribute to approximately $0.007 of a 5.3oz cup of yogurt’s cost. Usually, fruit, packaging material, milk, and labor contribute to most of the cost to make your product.

LABELING AN D MARKETING

D MARKETING

Probiotics and claims

Be careful advertising the effects of consuming your yogurt. Are you looking to make a structure-function claim? Read more here. You will likely need to make several culture considerations in order to accomplish this. The types of cultures needed are generally more expensive, as they have undergone clinical human trials.

OTHER CONSIDERATIONS

- Whey protein denaturation potential – impacts your flexibility to achieve various textures and water-holding capacities

- Vat pasteurization vs. HTST

- Hold time and temperature capabilities

- Are you planning to make different-sized SKUs? (e.g. 32oz and 5.3oz) – processing techniques may be modified for different SKUs

- How do you want to label cultures?

- Keep it simple: milk, cultures

- “Kitchen sink” it: listing every genus and species present

- Resets per day and phage considerations – unlike cheese cultures, there may not be a bacteriophage rotation.

- Are you using a co-manufacturer? – depending on the complexity of your yogurt culture, you may want to consider having Dairy Connection custom blend a culture for you to keep batching easy on your manufacturing partner and to protect your propriety recipe

- Target shelf life – the use of HOLDBAC or other biopreservatives may be in your best interest

YOGURT DEVELOPMENT APPROACHES

The technical staff at Dairy Connection will best be able to give recommendations when you are familiar with your culture and process. Even if you are not familiar with the yogurt make procedure, the Dairy Connection technical staff are well-acquainted with available cultures and can help you review your options. With new developments, a common route to follow is to trial a few stock cultures, compare, and give feedback to a member of our technical team so that adjustments may be considered (if needed) to achieve your target.

Sources

- 21 CFR § 131.200 Standard of Identity for Yogurt. 2018. https://www.ecfr.gov/cgi-bin/text-idx?SID=3f20ac5cafae4f8172c5398dd53c68e7&mc=true&node=se21.2.131_1200&rgn=div8

- Smith, Karen. Wisconsin Center for Dairy Research. 2008. Dried Dairy Ingredients. https://www.cdr.wisc.edu/sites/default/files/insider/resources/dried_dairy_ingdients.pdf

- Tetra Pak. 2015. Dairy Processing Handbook. Fermented Milk Products. https://dairyprocessinghandbook.com/chapter/fermented-milk-products

- U.S. Food and Drug Administration. 2017. Structure/Function Claims. https://www.fda.gov/food/food-labeling-nutrition/structurefunction-claims

Recent Blog Posts

-

New Cheese Coating Supply Now Available

By: Bill Rufenacht | Technical Specialist, Dairy Connection Inc.If you use cheese-coating as part o …5th Sep 2024 -

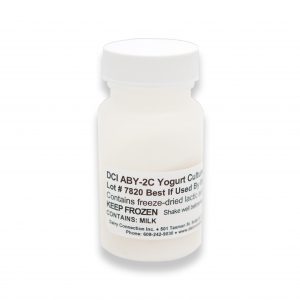

Featured Product: YoMix© ABY-2C Yogurt Culture

By: Bill Rufenacht | Technical Specialist, Dairy Connection Inc.YoMix© ABY-2C is a yogurt …2nd Apr 2024 -

Featured Product: Bioprotective Cultures

By: Bill Rufenacht | Technical Specialist, Dairy Connection Inc.Let’s take a look at bioprotective …15th Feb 2024